This system includes 2 layer palletizer for water and beverages, both connected at the output to the same winder, and some other devices, all designed, produced and tested in our main plant.

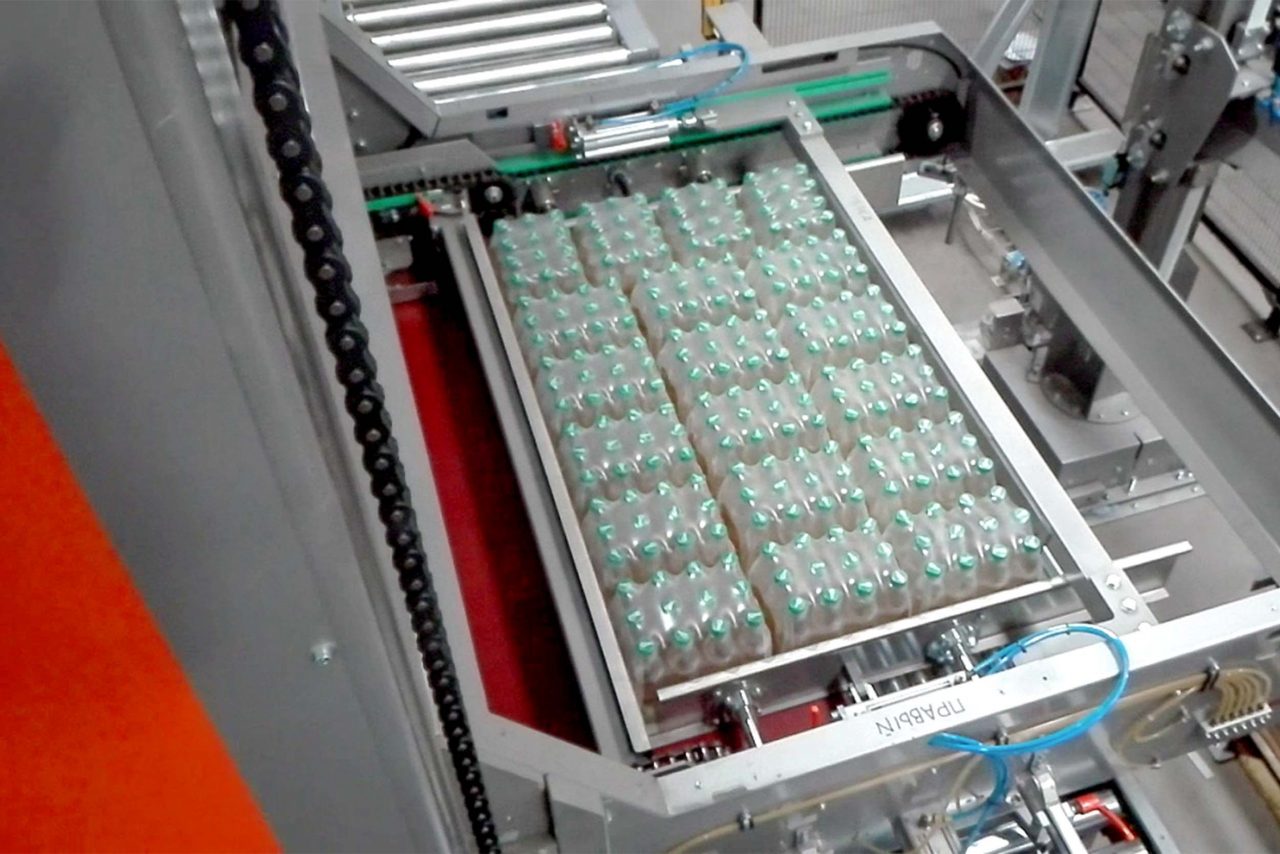

The customer’s requirement is to have a machine able to automatically arrange 3 types of bundles containing PET bottles on pallets; all of it will be managed by the operator and arranged in the warehouse.

Bundles sizes change depending on the type of bottle (from 0,33 to 1,5 l) and the inserting scheme (3×2, 4×3 or 5×4) with different pallet heights depending on the type, one only type of pallet (800×1200 h145) to face a production between 1000 and 4000 bundles per hour.

The supply is completed by a number of devices: full bundles conveying, layer preformer, middle-layer, warehouse and palette conveying, protections and accident prevention devices.

- Safety (Protections all over the system perimeter)

- Versatility (management of 3 different formats)

- Customization (warehouse with motorized retractile pallets))